“Axalta Irus Mix has quickly become an essential part of our daily work. It really is a great support in the color mixing process. It is easy to use, fast and precise. It is also flexible, so I can mix small quantities as well as large. One of the things I appreciate most is that I can do other work while the paint is being mixed by Axalta Irus Mix. I would wholeheartedly recommend Axalta Irus Mix to other bodyshops. It is the future of our industry.”

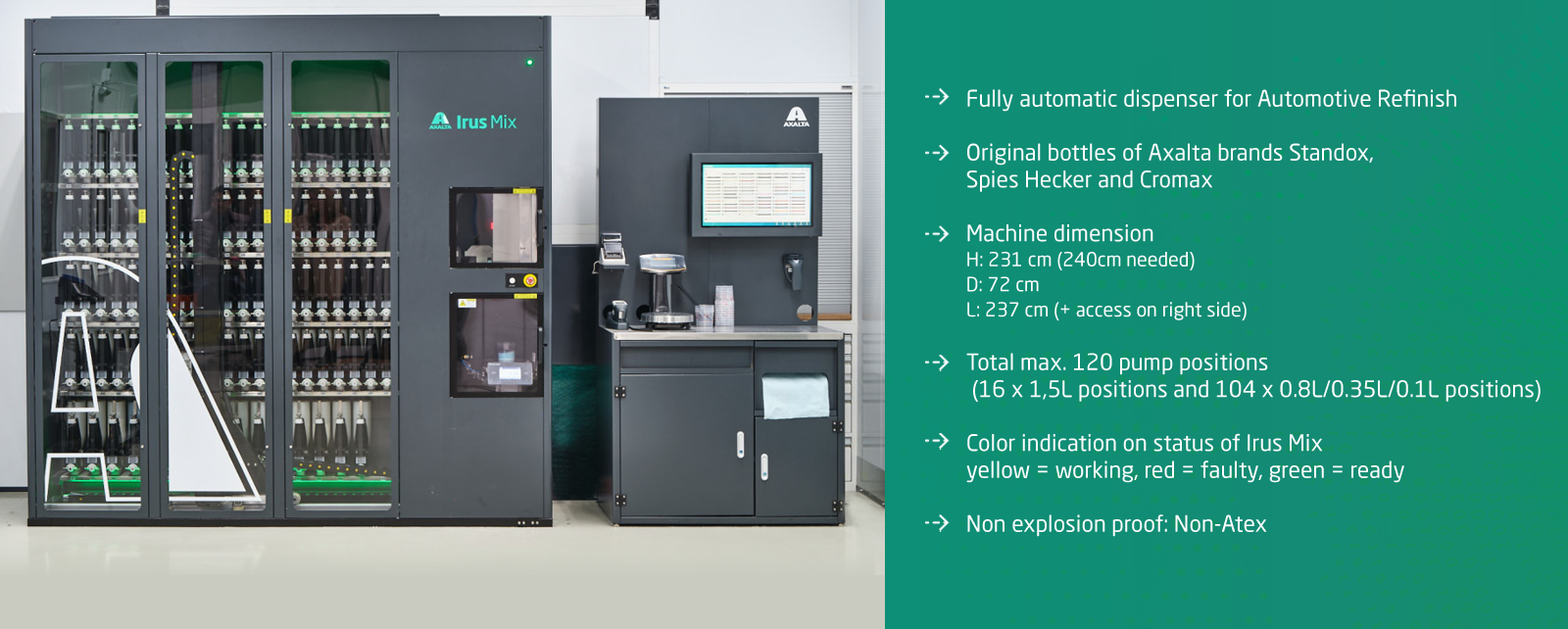

Axalta Irus Mix Features

- Fully automatic dispenser for Automotive Refinish

- Original bottles of Axalta brands Standox, Spies Hecker and Cromax

- Machine dimension:

H: 231 cm (240 cm needed)

D: 72

L: 237 cm (+ access on right side)

- Total max. 120 pump positions (16 x 1,5L positions and 104 x 0.8L/0.35L/0.1L positions)

- Color indication on status of Irus Mix

yellow = working, red = faulty, green = ready - Non explosion proof: Non-Atex

PUMP UNITS – accurate and durable

- Auto pick & placing of pump units

- Pump units with punch tool for vented bottles

- Unique positioning of pump units in Irus Mix

- Piston pumps for high speed dosing

- 3-way valve; simple durable, reproducable

- Warning levels to indicate replacing bottle

ROBOT ARM – high-speed placement

- Robot picks and shakes pump unit, moves left/right and up/down along rails,

- Delivers pump unit to dispensing position

- Picks up the next pump unit while dispensing

- Robot delivers pump unit to its correct position after dispensing

- High speed placement

- Daily maintenance (2 x) of each pump unit to secure stability of the tints (no interruption of work)

DISPENSING – fully autonomous

and extremely precise

- Fully controlled dispensing by 50ml piston pumps

- Direct interfacing with scale

- Starts always with biggest component

- Minimum shot size 0.05gr

- Automatic nozzle cleaning after dispensing

SCALE – highly accurate and user-friendly

- Operator friendly

- Automatic can table (space to put scale and cup)

- Including scale up to 7,5 kgs for accurate results, minimum accuracy 0.05gr

- Display for visual check

- Laser positioning

- Full visibility on dispensing process

- Direct communication with software

- Software driven instructions for placing mixing cups

- Scale to go down to exit position when ready

Ebubekir Kurt

Refinisher, Jülicher Lack- und Karrosseriecenter GmbH.

Jülich, Germany